Bubuka

Manual ieu nyayogikeun inpormasi penting pikeun panggunaan Papan Kontrol Tungku Pangganti OEM Carrier HK42FZ027 anu aman sareng efektif. Komponen kualitas luhur ieu dirancang pikeun ngagentos papan kontrol tungku produsén peralatan asli (OEM) dina sistem tungku Carrier anu cocog, pikeun mastikeun operasi sareng kontrol anu leres pikeun sistem pemanasan anjeun.

Émbaran Kasalametan

Parentah Kasalametan penting

- BAHAYA: Bahaya Kejutan Listrik. Cabut sadaya daya tina tungku di panel layanan utama sateuacan masang atanapi ngalayanan papan kontrol ieu. Upami henteu, éta tiasa nyababkeun tatu parah atanapi maot.

- Personil anu mumpuni Wungkul. Pamasangan sareng ngalayanan ngan ukur kedah dilakukeun ku teknisi HVAC anu mumpuni.

- Pancegahan Ngaluarkeun Uap Statis. Komponén éléktronik sénsitip kana listrik statis. Tangani papan kontrol ku sisi-sisina sareng anggo pancegahan ngaleupaskeun muatan éléktrostatik (ESD) anu pas.

- Pariksa Kompatibilitas. Pastikeun papan kontrol ieu (HK42FZ027) mangrupikeun bagian pangganti anu leres pikeun modél tungku khusus anjeun sateuacan dipasang.

- Akurasi Kabel. Pariksa deui sadaya sambungan kabel ngalawan diagram kabel tungku pikeun nyegah karusakan kana papan kontrol atanapi tungku.

Produk Leuwihview

Idéntifikasi komponén

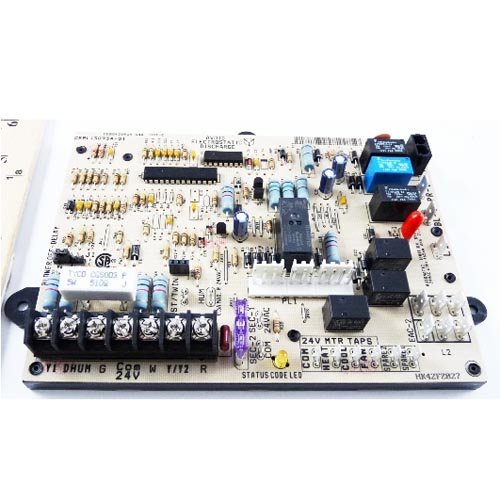

Papan kontrol tungku Carrier HK42FZ027 nyaéta unit pamrosésan pusat pikeun tungku anjeun, ngatur rupa-rupa fungsi sapertos pengapian, operasi kipas, sareng wates kaamanan. Di handap ieu gambar papan kontrol kalayan daérah konci sareng komponén anu katingali.

Katerangan Gambar: Gambar ieu nampilkeun papan kontrol tungku Carrier HK42FZ027. Papan ieu mangrupikeun papan sirkuit pasagi panjang anu dieusi ku rupa-rupa komponén éléktronik kalebet relay (komponén pasagi panjang biru sareng hideung), kapasitor (komponén silinder), resistor, sareng sirkuit terpadu. Fitur-fitur anu unggul kalebet:

- Blok terminal pikeun voltase handaptagkabel termostat (dilabélan Y1, DHUM, G, C, W, Y/Y2, R).

- LED kode status pikeun indikasi diagnostik.

- Kran motor 24V (dilabélan COM, HEAT, COOL, FA, SPARE).

- Terminal tambahan pikeun EAC-2 sareng L2.

- Rupa-rupa labél sapertos "ST/TWIN", "HUM", "SEC-2 SEC-Y COM 24VAC" nunjukkeun fungsi atanapi sambungan khusus. Nomer modél "HK42FZ027" katingali jelas dina papan.

Setup sareng Instalasi

Prosedur Instalasi

Turutan léngkah-léngkah ieu kalawan saksama nalika masang papan kontrol pangganti. Salawasna utamakeun kaamanan.

- Pegatkeun daya: Pareuman sadaya daya listrik ka tungku di panel layanan utama sareng di saklar pegatkeun sambungan lokal tungku.

- Ngahapus Panel Aksés: Cabut panel aksés tungku pikeun ngalaan papan kontrol anu tos aya.

- Wiring Dokumén: Potret atanapi sketsa sambungan kabel anu tos aya kana papan kontrol anu lami kalayan ati-ati. Labeli sadaya kabel pikeun sambungan deui anu akurat. Léngkah ieu penting pisan pikeun pamasangan anu leres.

- Pegatkeun sambungan kabel: Cabut sadaya kabel tina papan kontrol anu lami.

- Hapus Papan Lama: Cabut papan kontrol anu lami tina sasis tungku.

- Pasang Papan Anyar: Pasang papan kontrol Carrier HK42FZ027 anu anyar di lokasi anu sami, pastikeun papan éta parantos dipasang kalayan pageuh.

- Sambungkeun deui Wiring: Sambungkeun deui sadaya kabel ka papan kontrol anyar numutkeun dokuméntasi anjeun. Pariksa deui unggal sambungan pikeun akurasi.

- Panel Aman: Pasang deui panel aksés tungku.

- Mulangkeun Daya: Mulangkeun kakuatan listrik kana tungku.

- Operasi tés: Mimitian siklus pemanasan atanapi pendinginan pikeun mastikeun operasi tungku anu leres. Perhatikeun kode status LED pikeun indikasi diagnostik naon waé.

Catetan: Upami anjeun teu yakin kana léngkah naon waé, konsultasi ka teknisi HVAC anu mumpuni. Pamasangan anu teu leres tiasa nyababkeun karusakan alat atanapi cilaka pribadi.

Prinsip Operasi

Kumaha Papan Kontrol Fungsina

Papan kontrol HK42FZ027 bertindak salaku unit pamrosésan pusat sistem tungku anjeun. Papan ieu nampi sinyal ti termostat sareng rupa-rupa alat kaamanan pikeun ngontrol runtuyan operasi, mastikeun pemanasan anu efisien sareng aman. Fungsi konci kalebet:

- Runtuyan ignition: Ngatur timing sareng palaksanaan anu tepat tina prosés pengapian burner.

- Operasi Kipas: Ngontrol kipas blower jero ruangan pikeun modeu pemanasan, pendinginan, sareng kipas kontinyu dumasar kana paménta termostat.

- Pangimeutan Kasalametan: Terus-terusan ngawaskeun rupa-rupa wates kaamanan (contona, suhu luhur, sénsor seuneu) sareng ngamimitian mareuman kaamanan upami aya gangguan anu dideteksi, sering dituduhkeun ku LED kode status.

- Kontrol Asesoris: Bisa ngatur komponén bantu sapertos pelembab hawa atanapi pembersih hawa éléktronik anu disambungkeun ka terminal khusus dina papan.

Pangropéa

Perawatan sareng Inspeksi

Papan kontrolna sorangan mangrupikeun komponén éléktronik anu disegel sareng meryogikeun pangropéa langsung anu minimal. Nanging, pamariksaan rutin kana sistem tungku sacara umum disarankeun pikeun mastikeun umur panjang sareng fungsina anu leres.

- Inspeksi taunan: Pariksa tungku anjeun unggal taun ku teknisi HVAC anu mumpuni. Pamariksaan ieu kedah kalebet mariksa papan kontrol sareng sambunganna pikeun tanda-tanda karusakan, korosi, atanapi kabel anu leupas.

- Kabersihan: Pastikeun daérah di sakitar papan kontrol dijaga bébas tina lebu sareng runtah anu kaleuleuwihi, anu tiasa ngahalangan aliran hawa sareng pendinginan komponén.

- Hindarkeun Uap: Jaga papan kontrol sareng sakumna area tungku tetep garing pikeun nyegah korsleting listrik sareng korosi.

Pamérésan masalah

Masalah Umum sareng Diagnostik

LED kode status dina papan kontrol nyayogikeun inpormasi diagnostik anu berharga. Nalika aya gangguan, LED bakal kedip-kedip dina runtuyan anu khusus. Tingali manual layanan khusus tungku anjeun pikeun daptar lengkep kode flash sareng hartosna anu saluyu.

- Henteu aya kakuatan: Pariksa pemutus sirkuit sareng saklar pemutus listrik tungku. Pastikeun sadaya sambungan kabel kana papan kontrol pageuh.

- Tungku Teu Bisa Dihurungkeun: Pariksa setélan termostat. Pariksa kode kasalahan dina LED status. Pastikeun suplai gas hurung sareng igniterna jalan.

- Kipas Teu Jalan: Pariksa setélan kipas termostat. Pilari kode kasalahan anu aya hubunganana sareng kipas dina LED status.

- Operasi intermittent: Ieu tiasa nunjukkeun sambungan anu leupas, sénsor anu rusak, atanapi gangguan anu teu eureun-eureun dina papan. Konsultasikeun ka teknisi anu mumpuni pikeun diagnosis.

Awas: Ulah nyobian ngalereskeun papan kontrol sorangan. Disarankeun pikeun ngaganti ku teknisi anu mumpuni pikeun papan anu rusak.

spésifikasi

Spésifikasi produk

| Fitur | Rincian |

|---|---|

| Nomer modél | HK42FZ027 |

| merek | Operator (Pangganti OEM) |

| Dimensi produk | 6 x 6 x 6 inci |

| Item Beurat | 13 ons |

| Produsén | Pamawa |

| ASIN | B00FPOQWPI |

Garansi sareng Rojongan

Émbaran jaminan

Rincian garansi khusus pikeun suku cadang OEM ieu tiasa bénten-bénten gumantung kana anu ngajual sareng tanggal pameseran. Mangga tingali dokuméntasi pameseran anjeun atanapi hubungi anu ngajual langsung pikeun syarat sareng katangtuan garansi.

Bantosan Téknis

Pikeun bantuan téknis atanapi patarosan salajengna ngeunaan papan kontrol Carrier HK42FZ027, disarankeun pikeun ngahubungi profésional HVAC anu mumpuni. Pikeun dukungan produk resmi, mangga tingal dokuméntasi produsén alat asli (Carrier) atanapi websitus pikeun saluran dukungan anu diidinan.