1. Bubuka

This manual provides comprehensive instructions for the safe and efficient operation, setup, maintenance, and troubleshooting of your KATOOL ME Tire Changer and Balancer Machine Combo (Model 560+600). Please read this manual thoroughly before initial use and retain it for future reference. Understanding the procedures outlined herein will ensure optimal performance and extend the lifespan of your equipment.

2. Parentah Kasalametan

Adhering to these safety guidelines is crucial to prevent injury and equipment damage:

- Always wear appropriate personal protective equipment (PPE) including safety glasses, gloves, and steel-toed boots.

- Ensure the machine is properly anchored to a stable, level concrete surface before operation.

- Cabut daya sateuacan ngalakukeun pangropéa, panyesuaian, atanapi beberesih.

- Jaga leungeun, rambut, sareng pakean anu longgar tina sadaya bagian anu gerak salami operasi.

- Do not exceed the maximum tire diameter or wheel width specifications for the machine.

- Pastikeun ventilasi nyukupan di wewengkon gawé.

- Ngan tanaga anu dilatih kedah ngoperasikeun alat ieu.

3. Produk Langkungview

The KATOOL ME Tire Changer and Balancer Machine Combo (Model 560+600) is a professional-grade system designed for efficient tire service. It combines a robust tire changer with a precision wheel balancer, featuring advanced functionalities for various tire sizes.

Figure 3.1: KATOOL ME Tire Changer and Balancer Machine Combo.

Fitur konci:

- Tire Changer: Rim clamp outside: 10"-20", Rim clamping inside: 12"-24", Max. tire diameter 37", Max. wheel width: 12".

- Bead Blaster + Assist Arm: Facilitates easier tire removal and mounting, especially for stiff or low-profile ban.

- Konstruksi awét: Mounting head made of stainless steel with plastic cover for rim protection. Alloy steel jaws with carburization treatment for enhanced durability.

- Balancer kabayang: Digital display with dedicated ALU programs for precise balancing.

- Auto-Measuring System: One-touch system for accurate rim data (A, D) with ALU-S Mode.

- Motor efisien: 120V/1ph/1.5HP motor (North America) for strong power and high efficiency.

- Integrated Air Filter: High-quality filter for reliable oil drop and effective pressure air filtration, extending pneumatic system life.

4. Unpacking jeung Majelis

The KATOOL ME Tire Changer and Balancer Machine Combo is shipped in two separate crates on pallets. Due to the weight and size, it is recommended to have assistance during unpacking and assembly.

- Carefully remove all packaging materials from both crates. Inspect all components for any signs of damage. Report any damage to the carrier and supplier immediately.

- Refer to the detailed assembly diagrams provided in the manufacturer's full manual for connecting the tire changer and balancer units.

- Ensure all pneumatic and electrical connections are securely fastened and correctly installed. It is recommended that a qualified technician performs these connections.

- The package includes an assist arm. Attach it according to the assembly instructions.

5. Setélan

Proper setup is essential for safe and effective operation.

5.1 Anchoring Mesin

The machine must be securely anchored to a concrete floor to prevent movement during operation. Use appropriate anchor bolts (not included) and follow local building codes and safety regulations for installation.

5.2 Sambungan Daya

Connect the machine to a dedicated 120V/1ph/1.5HP power supply (for North America). Ensure the electrical circuit can handle the machine's power requirements without overloading. Consult a qualified electrician if unsure.

5.3 Sambungan suplai hawa

Connect a clean, dry air supply to the pneumatic system. The machine includes a high-quality filter for reliable drop oil and effective air pressure filtration, which contributes to the longevity of the pneumatic components.

Figure 5.1: Approximate dimensions of the KATOOL ME Tire Changer. Height: 77 inches, Base Width: 20 inches, Base Depth: 33 inches, Turntable Height: 28 inches.

6. Parentah Operasi

6.1 Tire Changer Operation

- Persiapan: Apply tire lubricant to the tire beads and rim edges to facilitate easier mounting and demounting.

- Bead Breaking: Position the tire on the bead blaster. Use the pedal control to activate the bead blaster and break the tire bead from the rim.

Figure 6.1: Using the bead blaster to separate the tire from the rim.

Figure 6.2: The tire is securely fixed on the turntable for further operations.

- Pamasangan / Demounting: Place the wheel on the turntable. Secure the wheel using the clamping jaws. Use the mounting head and assist arm to carefully demount or mount the tire. The mounting head is designed with a plastic cover to protect the rim.

Figure 6.3: Demounting a tire from the wheel using the tire changer.

Figure 6.4: The auxiliary arm assists in removing tires, providing additional leverage.

- Inflasi: Use the integrated inflation gauge with pedal control to inflate the tire to the manufacturer's recommended pressure.

Figure 6.5: Foot pedals for automatic operation of the tire changer functions.

6.2 Wheel Balancer Operation

Figure 6.6: KATOOL ME Wheel Balancer (Model ME-B600) with accessories.

- Pasang Roda: Securely mount the wheel onto the balancer's shaft using the appropriate cones and quick-release nut.

- Input Data: Use the auto-measuring system to obtain precise rim data (A, D) with ALU-S Mode. The digital display provides clear readings.

Video 6.1: Demonstration of the BILT HARD Wheel Balancer, showing wheel mounting, data input, and balancing process. This video illustrates the general operation of a wheel balancer.

- Balancing Cycle: Initiate the balancing cycle using the 'START' button on the control panel. The machine will spin the wheel and calculate the required weight and placement.

- Weight Placement: The machine indicates the precise location for weight placement. Use the built-in clip slot for quick and easy weight application.

Figure 6.7: Applying balance weights to the wheel rim using the provided tool.

- Pariksa deui: Perform a re-check spin to confirm proper balance.

Figure 6.8: The digital control panel of the wheel balancer, showing measurement data and program selection.

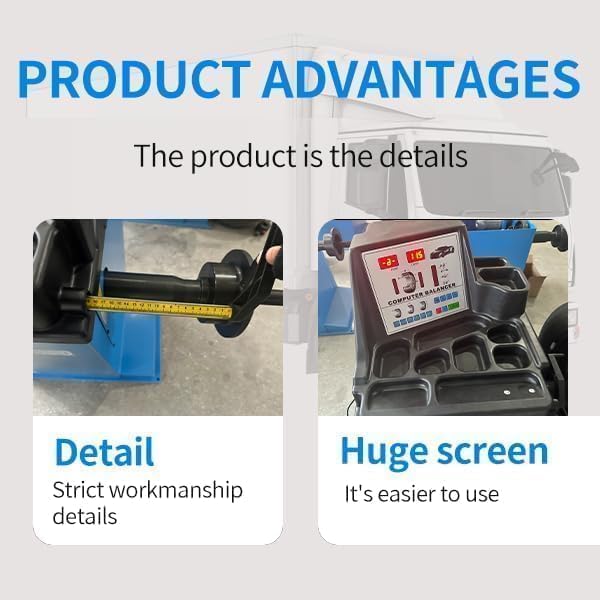

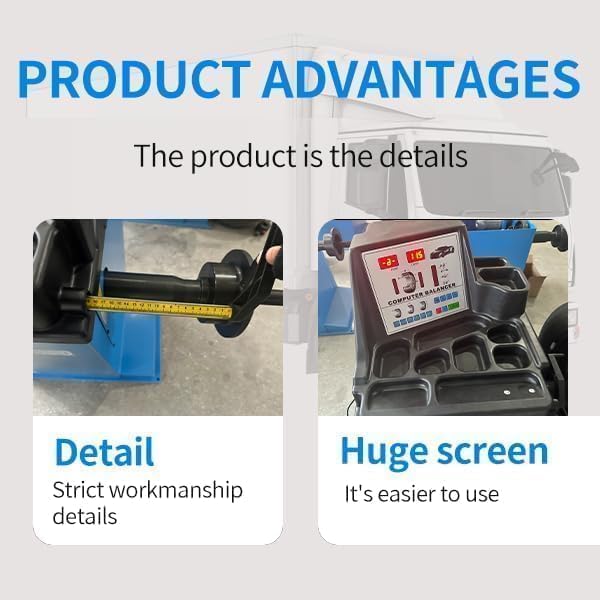

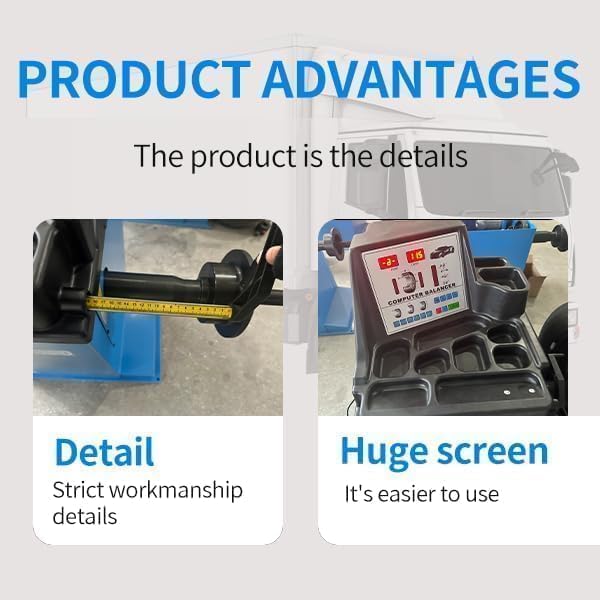

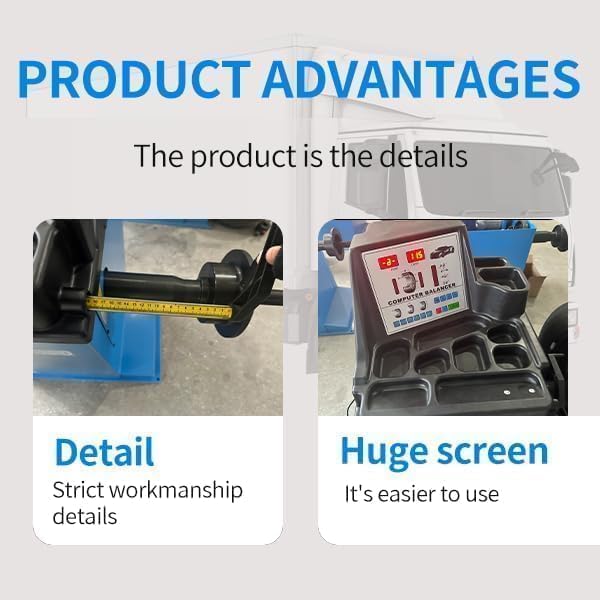

Gambar 6.9: Rincian view of the wheel balancer's strict workmanship and large, easy-to-use screen.

7. Pangropéa

Regular maintenance ensures the longevity and optimal performance of your KATOOL ME Tire Changer and Balancer Machine Combo.

- beberesih poean: Keep the machine clean from tire debris, dust, and lubricant residue. Use a damp lawon jeung detergent hampang.

- Lubrication: Regularly lubricate moving parts as indicated in the detailed manufacturer's manual. Pay attention to the clamping jaws, turntable, and assist arm mechanisms.

- Pangropéa saringan hawa: Periodically check and clean or replace the air filter to ensure optimal pneumatic system performance and longevity. A clogged filter can reduce efficiency.

- Jaw Maintenance: Inspect the alloy steel jaws for wear or damage. The interface carburization treatment ensures tenacity and hardness, but regular inspection is vital. Replace jaw covers as needed to protect rims from scratches.

- Mounting Head Inspection: Check the stainless steel mounting head for wear or damage. Ensure the plastic cover is intact to prevent rim damage.

- Sambungan listrik: Periodically inspect all electrical connections for tightness and signs of wear or corrosion.

8. Cara ngungkulan

Bagian ieu ngabahas masalah umum anu anjeun tingali. Pikeun masalah nu leuwih kompleks, kontak rojongan customer.

8.1 Tire Changer Troubleshooting

- Mesin teu hurung: Check the power connection, circuit breaker, and ensure the emergency stop button is not engaged.

- Tire Not Seating Properly: Ensure proper lubrication of tire beads and rim. Verify bead blaster pressure. Check for any damage to the rim or tire that might prevent proper seating.

- Clamping Jaws Not Operating: Check air supply pressure and pneumatic connections. Inspect foot pedal mechanisms for obstructions.

8.2 Wheel Balancer Troubleshooting

- Balancing Inaccuracies: Re-enter rim data carefully. Ensure the wheel is securely mounted on the balancer shaft. Clean the wheel and rim thoroughly to remove any debris or old weights. Check for bent rims or damaged tires.

- Machine Not Spinning: Verify power connection. Check for any obstructions preventing wheel rotation. Ensure safety cover is properly closed (if applicable).

For complex issues or problems not listed here, contact KATOOL customer support or a qualified service technician.

9. Spésifikasi

| Fitur | Spésifikasi |

|---|---|

| Modél | 560+600 |

| Tire Changer Rim Clamp (Di luar) | 10"-20" |

| Tire Changer Rim Clamp (Di jero) | 12"-24" |

| Max. Diaméter ban | 37" |

| Max. Lebar kabayang | 12" |

| Motor (North America) | 120V/1ph/1.5HP |

| Mounting Head Material | Stainless steel with plastic cover |

| Bahan Jawo | Alloy steel, carburization treated |

| Sistim Pneumatic | High-quality filter for reliable drop oil |

| Wheel Balancer Programs | Dedicated ALU Programs, ALU-S Mode |

| Wheel Balancer Measurement | Auto-measuring system for rim data (A, D) |

10. Naon dina Box

The KATOOL ME Tire Changer and Balancer Machine Combo includes the following main components:

- Tire Changer Unit

- Wheel Balancer Unit

- Pitulung Arm

- Mounting Head with Plastic Cover

- Inflation Gauge with Pedal Control

- Standard Accessories for Tire Changer and Balancer (e.g., cones, quick-release nut, weight pliers, etc.)

11. Garansi jeung Rojongan

For detailed warranty information, terms, and conditions, please refer to the warranty card or documentation included with your product. If you require technical assistance, have questions about operation, or need to report an issue, please contact KATOOL customer service through the contact information provided in your product packaging or on the official KATOOL websitus.